Digital Orthoimagery

Planning for Success: Project Design

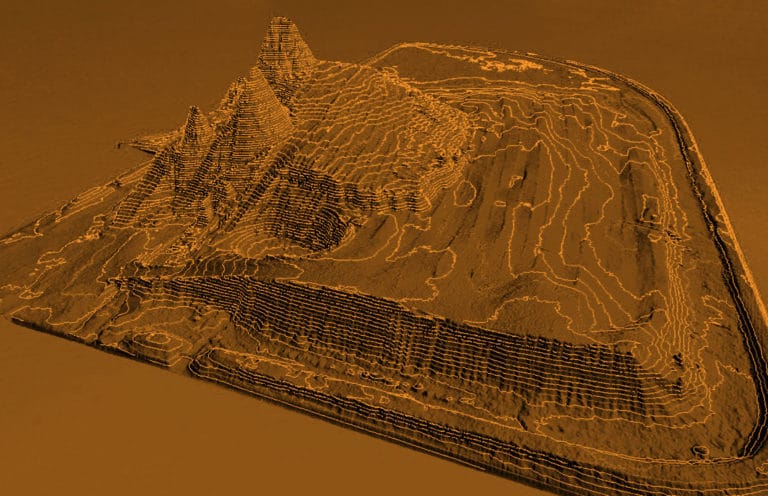

Digital orthoimagery is a seamless aerial image of the Earth’s surface. Beneath a digital orthoimage lies a three-dimensional surface model that accurately depicts the shape and form of the terrain. The imagery is measured against known points on the Earth that are verified by GPS to ensure the imagery meets accuracy requirements.

Surdex carefully designs each project with the required survey control, the most suitable sensor and aircraft, and the optimal flying height to ensure optimal image resolution, mapping accuracy and collection efficiency. Design elements include:

- Terrain (farmland, urban, coastal, forest, etc.)

- Resolution

- Features desired to be captured, if the project includes mapping

Surdex will calculate the flying height required for the resolution (3”, 6”, or 12” GSD, for example), coupled with the control points dictated by the accuracy requirements. Then an aircraft / sensor combination is chosen which offers the best collection. Follow this link to see samples of orthoimagery at different resolutions.

A winning design provides for the most efficient approach, with the fewest flight lines necessary in order to achieve the desired accuracy and resolution.

Image Processing

Following aerial acquisition, imagery is processed to orient it to known coordinates, refine the color balance, and remove irregularities. These processes provide clients with premium image quality guaranteed to meet your specifications.

To make continuous, seamless imagery, individual frames or strips of imagery are orthorectified and the color is balanced. This process includes:

- Rectifying the imagery to known coordinates on the ground

- Processing the imagery so the many separate images create a continuous, seamless image

- Balancing color to ensure tonal quality and consistency throughout the project

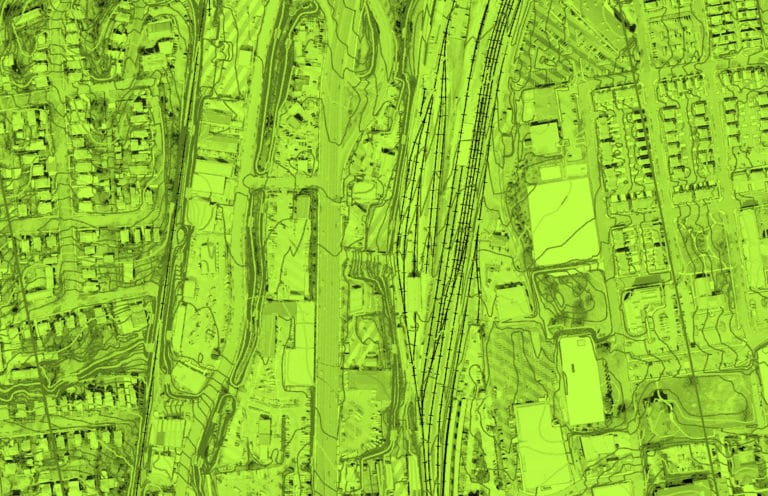

The resulting digital imagery of surface features in their geometrically-corrected positions is free of the inaccuracies inherent in simple rectified photographs.

Once the orthoimagery is complete, any type of planimetric, topographic or cadastral data may be overlaid within a Geographic Information System (GIS) so that the user may quickly and easily find the information pertaining to an identifiable object.

Process Details

Acquisition

It is extremely important to keep aircraft crews acquiring imagery so data processing can begin and all projects can remain on schedule. Surdex takes these steps to keep the acquisition pipeline full:

- The aircraft and sensor designated for a project are placed on the schedule

- Weather is continuously monitored to ensure our resources are taking advantage of every window of opportunity for acquisition

Should weather become unsuitable in one region, crews are mobilized to other regions and other projects.

Technology

Surdex owns and operates a host of advanced digital imagery sensors.

- Leica ADS100 Airborne Digital Sensor (five)

- As a pushbroom sensor, it acquires imagery in a continuous strip and is ideal for large area acquisition

- Its wide collection swath reduces acquisition time

- Leica DMC-1 Digital Frame Camera (four)

- Large-format digital camera system comprised of eight individual cameras; ideal for mid-size and smaller projects and for mapping projects

- Phase One iXU-RS Digital Frame Camera (one)

- Simultaneous acquisition of imagery with a LiDAR sensor, which saves time and cost by reducing the number of flights required

- Leica RCD30 Airborne Digital Camera (one)

- Medium-format system for urban mapping and corridor mapping; configured for oblique imagery

Quality Control

Surdex has instituted ISO Quality Control and Quality Assurance measures in each department. Image color and project specifications are clarified before work begins, and all products are inspected before delivery to our clients.

Quality Control processes are under continuous review and refinement. Imagery is inspected and validated at each stage of production, from acquisition through final delivery, to ensure no data progresses to the next phase of production without first being approved and validated as meeting all specifications.

Delivery

Our SurCheck online inspection tool streamlines the inspection, remedial action, and acceptance process and has been proven to simplify and reduce overall project timelines. Surdex uses it internally and makes it available to clients for their own inspection and validation.

Imagery Samples